Introduction

In high-risk environments, Personal Protective Equipment (PPE) is not just a legal requirement; it is a crucial element in ensuring the safety of workers. But with various risks involved, how can businesses choose, correctly use, and optimize the effectiveness of PPE? This article provides actionable PPE management strategies from the perspectives of feasibility, effectiveness, and practicality, while also exploring potential technological advancements that can enhance safety in the workplace.

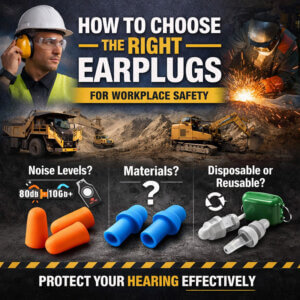

1. Key Points in Choosing PPE for High-Risk Environments

Select the Appropriate PPE Level

When selecting PPE in high-risk environments, it is important to match the protection level to the specific work hazards. For example, chemical-resistant gloves, heavy-duty helmets, and explosion-proof goggles all require different levels of protection depending on the type of risk. Overprotection may lead to unnecessary discomfort, while underprotection can increase the likelihood of accidents.

Case Study:

According to research by OSHA (Occupational Safety and Health Administration), construction industries saw a 20% reduction in injury rates when workers used PPE that matched the specific risks involved, such as high-impact helmets and splash-resistant goggles to prevent head injuries or eye damage from flying debris.

Durability and Comfort

In high-risk environments, the durability and comfort of PPE are crucial. High-quality protective clothing should not only be durable and waterproof but also breathable, reducing discomfort for workers during extended wear. Comfortable equipment enables workers to focus on their tasks rather than being distracted by discomfort.

Data Support:

Studies show that in the oil and gas industry, employees who wore comfortable and breathable PPE were 15% more productive. Workers were also more willing to wear their PPE for longer periods, significantly reducing safety incidents.

2. How to Extend PPE Lifespan through Regular Inspections and Maintenance

Regularly Inspect Equipment

Regularly inspecting PPE, especially frequently used items such as face masks and gloves, can significantly extend their lifespan. Inspections should focus on wear and tear, cracks, contamination, and other damage. Timely replacement of damaged items ensures that PPE continues to provide reliable protection when needed most.

Case Study:

A large construction company reported a 30% reduction in PPE damage rates and a decrease in accidents due to equipment failure after implementing monthly PPE inspections, setting a new standard in the industry.

Proper Storage and Cleaning

Proper storage and maintenance are essential to prolong the life of PPE. Avoid exposing gear to direct sunlight or storing it in damp environments. For protective eyewear and face shields, regular cleaning of lenses and filters ensures clear vision and optimal respiratory function. Keeping PPE clean also helps maintain its effectiveness.

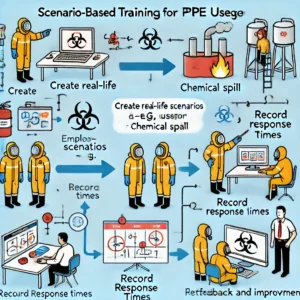

3. Innovative Employee Training Methods to Improve PPE Usage

Scenario-Based Training

To help workers react quickly in emergencies, scenario-based training is an effective approach. By simulating situations such as chemical spills or equipment malfunctions, employees can practice how to quickly put on and use PPE in real-life environments, improving their ability to respond in critical situations.

Case Study:

After implementing scenario-based training, a global chemical company found that employees’ response times in actual accidents were reduced by 25%, significantly reducing the risks associated with delayed reactions.

Enhancing Safety Awareness

Regular safety training sessions, posters, and campaigns help increase employee awareness of the proper usage of PPE and its importance. For example, videos showing the risks of improper PPE usage can effectively demonstrate the consequences of non-compliance.

4. Integrating Smart Devices to Enhance Safety Management Precision

Gradual Introduction of Sensor-Assisted Devices

While fully smart PPE devices are not yet widespread, some cost-effective sensor-based devices have already been introduced. Devices such as air quality sensors and noise monitors can provide real-time data to help employees assess whether additional protective measures are needed.

Data Support:

After introducing air quality sensors, a mining company reduced hazardous gas exposure by 87%. The real-time detection system allowed employees to act within 2 minutes of a gas leak, preventing serious health issues.

Future Outlook: The Potential of Smart PPE

With advances in technology, the future of smart PPE holds tremendous promise. Smart helmets and gloves are expected to become standard in the workplace. These devices monitor workers’ vital signs and alert them to potential hazards. For instance, a smart helmet could be equipped with sensors that track the intensity of head impacts, alerting the wearer if a dangerous impact occurs.

Technical Detail:

Smart helmets are being developed with accelerometers and gyroscopes that monitor head movements and impacts in real-time. If an impact exceeds a predetermined threshold, the system sends an alert via an LED display or a connected mobile app, notifying the worker of potential risks.

5. Establishing Feedback Mechanisms to Continuously Optimize PPE Usage

Create an Employee Feedback System

An effective feedback system allows employees to share their experiences and suggestions regarding PPE usage. For example, if workers consistently report fogging issues with certain goggles, management can consider switching to anti-fog models to improve comfort.

Case Study:

By establishing a feedback system, a large manufacturing company learned that workers found their safety boots too heavy, which affected their efficiency. After switching to lighter models, employee satisfaction increased by 40%, leading to better overall performance.

Safety Data Tracking and Analysis

Recording and analyzing data from safety incidents (e.g., PPE performance, environmental factors, employee actions) allows businesses to identify potential issues and make adjustments. For example, if a particular PPE item is found to underperform in specific conditions, it can be replaced with a more suitable alternative.

| Employee Feedback | Problem/Challenge | Improvement Action | Impact of Improvement |

|---|---|---|---|

| Safety boots too heavy | Affected work efficiency | Replaced with lighter boots | 40% increase in employee satisfaction |

| Goggles fogging up | Reduced comfort, impacted work | Switched to anti-fog goggles | Increased comfort, fewer complaints |

| Safety gloves not durable enough | Frequent damage, affecting efficiency | Replaced with more durable gloves | Extended glove life, reduced replacements |

Conclusion

Effectively using PPE in high-risk environments involves not only selecting and using the right equipment but also focusing on durability, comfort, and proper training. While smart PPE technology is still in its early stages, businesses can begin integrating cost-effective smart devices to explore more advanced safety management solutions. By continuously optimizing PPE usage through data analysis and employee feedback, companies can ensure ongoing safety in the workplace.

Take Action Now!

Choose the right PPE for your business and optimize your management processes to ensure your workers’ safety and comfort. Contact us to learn more about customized PPE solutions, or explore the latest innovations in smart PPE devices.