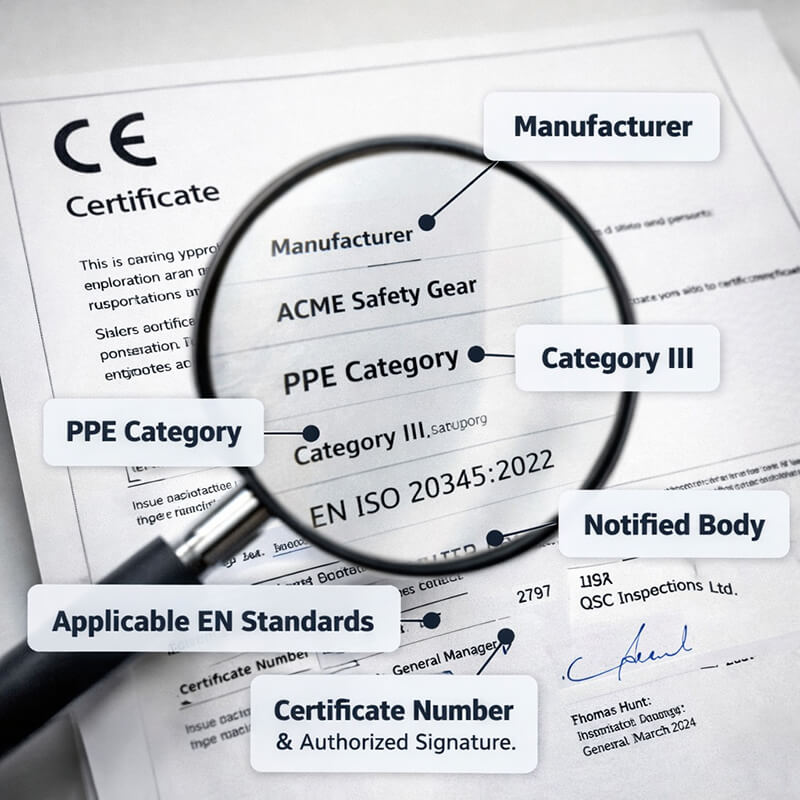

Which Parts of a CE Certificate Really Matter?

Not all details on a CE certificate matter equally. This article explains the key sections—manufacturer, PPE category, applicable EN standards, Notified Body, certificate number, and signature—so buyers can verify PPE compliance confidently.

ANSI vs EN: Why the Same Safety Gloves Perform So Differently?

The same pair of safety gloves can show very different performance levels under ANSI and EN standards. This article explains the key differences in testing methods and classification logic, helping buyers understand what the results really mean.

ANSI Cut Level A1–A9: What Buyers Most Often Overlook When Sourcing Cut-Resistant Gloves

ANSI cut levels A1–A9 are widely used when sourcing cut-resistant gloves, but relying on the rating alone can lead to costly mistakes. This article highlights the key factors buyers often overlook, from test methods and real-world applications to material choices and certification relevance.

Are EN 388 Letter Cut Levels Really More Reliable Than Numbers?

This article explains why EN 388 introduced letter cut levels (A–F), how they differ from traditional numeric ratings, and how buyers should interpret them in real working conditions.

NFPA 2112: The Importance of Industrial Flame-Resistant Clothing

NFPA 2112 is a critical standard for industrial flame-resistant clothing, designed to protect workers in high-risk industries such as oil, gas, chemical, and power generation. This article explains the key requirements, testing methods, material selection, and the importance of compliance for employee safety and regulatory adherence.

Safety Shoe Materials Explained: Steel Toe, Composite, and More – Pros & Cons

Learn the advantages and disadvantages of steel toe, composite, and other safety shoe materials to choose the best footwear for your work environment.

What Really Changes When Flame-Resistant Clothing Is Frequently Washed?

Frequent washing affects the appearance, fit, and secondary features of flame-resistant clothing, but the core protective fibers usually remain effective. Regular care and inspection are key to long-lasting safety.

Flame-Resistant + Anti-Static Clothing: Added Protection or a Misunderstood Safety Combination?

Flame-resistant and anti-static clothing is often seen as a higher level of protection, but its effectiveness depends on correct risk assessment and application. This article explains where the combination works—and where it is commonly misunderstood.

Why Choosing Flame Resistant Clothing Based Only on Fabric Weight Is a Common—and Dangerous—Mistake

Many buyers assume that heavier flame resistant clothing offers better protection. In reality, fabric weight only describes how heavy a garment is—not how it performs under thermal hazards. This article explains why relying on GSM alone can be misleading, and what truly matters when selecting flame resistant clothing for real-world safety.

Inherent vs Treated Flame-Resistant Fabrics: Which One Truly Protects Workers?

Inherent and treated flame-resistant fabrics offer different levels of protection. This article explains their characteristics, advantages, and limitations, helping employers select the right FR clothing for worker safety and thermal protection.

Why “Flame Resistant” Does Not Always Mean Real Thermal Protection

Flame-resistant clothing is designed to resist ignition and self-extinguish, but this does not automatically guarantee effective thermal protection. This article explains the critical differences between flame resistance and real heat protection, helping readers understand what truly matters when selecting FR clothing for high-temperature work environments.

From Dust to High Impact: The Fundamental Protection Logic Differences Between Blasting PPE and Painting PPE

Painting and abrasive blasting may look similar, but their PPE requirements are fundamentally different. This article explains how liquid penetration and high-impact abrasion define two completely different protection logics—and why these PPE types should never be mixed.