In modern workplaces, safety is always a top priority. Whether you’re a construction worker, manufacturing operator, healthcare professional, or work in any other high-risk occupation, ensuring the safety of yourself and your colleagues is crucial. Personal Protective Equipment (PPE) is a key tool to ensure workplace safety. So, what exactly is PPE, and how does it play a critical role in everyday work? This article will provide detailed answers, along with examples from specific industries like construction, manufacturing, and healthcare.

1. What is Personal Protective Equipment (PPE)?

Personal Protective Equipment (PPE) refers to gear or clothing designed to protect employees from potential hazards in their work environment. It covers protection from head to toe and aims to reduce or eliminate physical, chemical, biological, or electrical risks that could harm the human body.

There are several types of PPE, typically including:

- Head Protection: Such as hard hats, which prevent head injuries from falling objects or impacts.

- Eye Protection: Such as safety goggles or face shields, which protect eyes from splashes, chemicals, or harmful radiation.

- Respiratory Protection: Such as masks and respirators, which help filter harmful substances like dust, fumes, or chemical vapors from the air.

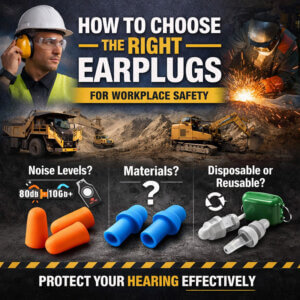

- Hearing Protection: Such as earplugs or earmuffs, which reduce noise-related hearing damage.

- Hand Protection: Such as protective gloves, used to prevent cuts, chemical exposure, or burns.

- Body Protection: Such as protective clothing, fire-resistant suits, or chemical-resistant suits, which protect the skin from chemicals, extreme temperatures, or abrasions.

- Foot Protection: Such as steel-toe boots or anti-slip shoes, which prevent foot injuries from heavy objects or slips.

- Fall Protection: Such as safety harnesses and lanyards, used in high-altitude work to prevent falls.

PPE in Specific Industries

In different industries, the application of PPE varies depending on the nature of the risks. Here are some industry-specific examples:

Construction Industry:

In construction, risks often involve falls from heights, heavy machinery, and falling objects. Workers typically use hard hats, safety harnesses, and steel-toe boots to protect themselves. A construction worker, for example, might wear a hard hat to protect against falling debris, while a safety harness prevents fatal falls when working on scaffolding or tall structures.

Manufacturing Industry:

Manufacturing workers face risks like exposure to sharp tools, high noise levels, and chemical spills. In a factory setting, protective gloves are essential to prevent cuts from machinery, while ear protection is crucial in loud environments. For workers exposed to chemicals, safety goggles and respirators help prevent harmful exposure to fumes or splashes.

Healthcare Industry:

In healthcare, the primary concern is exposure to infectious diseases and bodily fluids. Doctors and nurses wear PPE like N95 respirators, face shields, and disposable gloves to minimize the risk of infection, especially during surgeries or when dealing with contagious patients. Full-body protective clothing, such as gowns and face shields, is crucial in pandemic situations to avoid contamination.

2. The Importance of PPE: How Does It Protect Your Safety?

Workplace hazards come in many forms—from physical impacts to chemical burns, and even biological infections. PPE acts as a critical barrier, effectively isolating these potential dangers from the worker.

-

Reduces Direct Exposure Risks

PPE directly protects exposed areas of the body, preventing harmful substances from contacting the skin, eyes, ears, and other critical areas. For example, when handling toxic chemicals, wearing appropriate protective clothing and gloves significantly reduces the risk of exposure. In the healthcare field, a nurse using an N95 mask and face shield is protected from airborne pathogens when treating patients with respiratory infections.

-

Minimizes Injury Severity

In some situations, hazards cannot be completely avoided, but PPE can significantly reduce the severity of injuries. For instance, in manufacturing plants where workers handle heavy machinery, protective gloves and steel-toe boots help minimize injuries caused by sharp tools or falling objects. Similarly, in construction, a fall from a height could be life-threatening without a safety harness, but with one, the severity of injury is drastically reduced.

-

Boosts Overall Workplace Safety Awareness

PPE is more than just personal protection—it helps foster a safety culture within the organization. When employees wear PPE daily, they become more aware of potential risks, and the overall safety management of the company improves. This is especially critical in industries like construction, where workers often face various high-risk scenarios daily. Wearing a hard hat and high-visibility vest not only provides protection but also serves as a reminder to others of the surrounding dangers.

3. Why Must Your Workplace Follow PPE Standards?

In many countries and regions, workplace safety regulations require the use of PPE. For example, the Occupational Safety and Health Administration (OSHA) in the United States and CE certification in the European Union both mandate that employers provide employees with PPE that meets specific standards. Failure to comply with these regulations can lead to legal liabilities, employee injuries, damage to a company’s reputation, and significant financial losses.

Additionally, compliant PPE products are usually rigorously tested to ensure they provide reliable protection under specific conditions. For both employers and employees, choosing PPE that meets industry standards demonstrates a commitment to safety.

4. How to Ensure Proper Use of PPE?

Simply providing PPE is not enough; correct use and maintenance are equally important. Here are some key points:

1. Training:

Employees need comprehensive training to understand when to use PPE, how to properly wear and remove it, and how to identify damaged or unsuitable equipment.

2. Regular Inspections:

PPE should be regularly inspected to ensure it remains in good working condition. Critical equipment like respirators and protective suits should be tested before and after use.

3. Maintenance and Replacement:

Most PPE is not designed to last forever. Gloves, safety goggles, and masks, for example, may lose their protective effectiveness over time. Companies should implement a regular replacement schedule to ensure employees are always using functional PPE.

4. Developing Good Personal Habits:

In addition to company-provided training and guidelines, employees should develop good safety habits. They should not casually remove or neglect PPE usage and must always follow protocols strictly.

5. Conclusion

Personal Protective Equipment (PPE) is an indispensable safety tool in modern workplaces. It effectively protects employees from various potential hazards and helps companies comply with relevant laws and regulations, ensuring a safe working environment. Choosing appropriate PPE and using it correctly can significantly reduce the likelihood of accidents while improving employees’ sense of security and work efficiency.

Whether you are an employer or an employee, PPE use should be considered a fundamental safety measure. Safety is not just one person’s responsibility but a shared goal for the entire team. By equipping employees with proper PPE, you are not only safeguarding their well-being but also creating a more efficient and harmonious work environment.

Your safety, our shared responsibility!