In high-risk industries like construction and maintenance, a personal fall protection system is the last line of defense against catastrophic injuries. Comprising three critical components—full-body harnesses, fall arresters, and anchor points/connectors—this system works synergistically to absorb impact forces and prevent ground contact during a fall. This blog breaks down each component’s role, compliance standards, and best practices for system integration.

1. Full-Body Harness (EN 361): The Lifeline Interface

The harness is the only direct connection between the worker and the safety system. Compliant with EN 361, it distributes fall forces across the pelvis, chest, and thighs to minimize injury risks.

Key Features:

- Multi-Point Anchorage: D-rings (back, chest, or hip) rated for ≥15 kN static load (tested for 3 minutes).

- Ergonomic Design: Adjustable straps and breathable padding ensure mobility during prolonged use.

- Mandatory Certification: CE marking with a notified body number (e.g., 0123) for PPE Category III compliance.

Common Pitfalls:

- Misusing side D-rings (designed for positioning, not fall arrest).

- Skipping biannual inspections (monthly checks recommended in harsh environments).

2. Fall Arrester (EN 355): The Energy-Absorbing Lifesaver

The fall arrester, or energy absorber, is the system’s shock absorber. Governed by EN 355, it limits forces to ≤6 kN—the maximum safe threshold for the human body.

Critical Performance Criteria:

- Dynamic Testing: A 100 kg mass dropped from 4 meters must deploy ≤1.75 meters with ≤6 kN peak force.

- Static Strength: Withstands 15 kN for 3 minutes without failure.

- Corrosion Resistance: Metal parts pass 24–48-hour salt spray tests (essential for offshore/industrial use).

Types & Selection:

- Rigid Rail Systems: Use EN 353-1-certified devices (e.g., vertical lifelines on ladders).

- Flexible Systems: Opt for EN 353-2-compliant models with ≥8 mm wire rope or webbing.

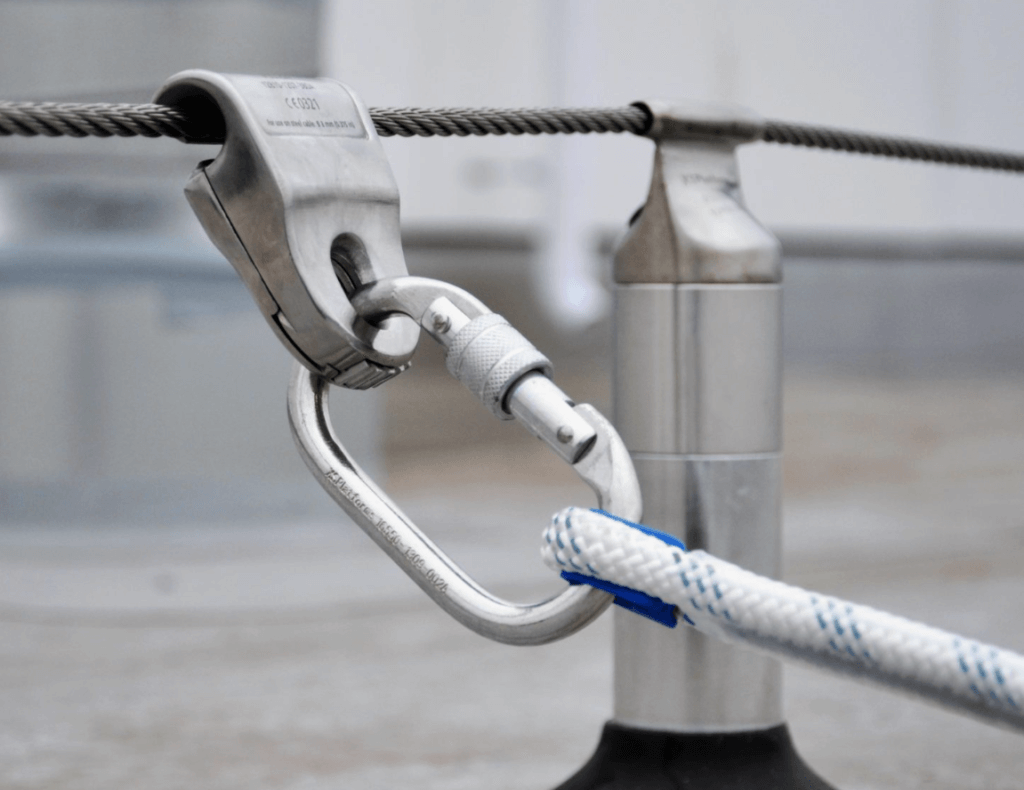

3. Anchor Points & Connectors (EN 795/EN 362): The Structural Backbone

Anchors and connectors transfer fall forces to stable structures. Their failure can render the entire system useless.

Compliance Requirements:

- Anchor Points (EN 795): Minimum 10 kN static load capacity, positioned overhead to prevent swing falls.

- Connectors (EN 362): Carabiners, hooks, or eye bolts rated for ≥15 kN, made of corrosion-resistant alloys.

Application Scenarios:

- Construction Sites: Steel I-beams or engineered anchors (avoid pipes/temporary rails).

- Confined Spaces: Tripod anchors (EN 795-C) with retractable lifelines for vertical rescue.

How the Three Components Work Together

During a fall:

- Anchor Holds Firm: Transfers forces to a load-bearing structure.

- Harness Distributes Load: Spreads impact across the body to prevent trauma.

- Arrester Absorbs Energy: Slows descent via webbing tear or mechanical deformation, keeping forces below 6 kN.

Critical Selection Tips

- Multi-Standard Compliance: Ensure compatibility—e.g., an EN 355 arrester must pair with EN 353-1/2 anchors.

- Calculate Total Fall Distance:

- Formula: Free fall distance (2 meters) + arrester deployment (≤1.75 meters) + harness stretch < total clearance.

- Environment-Specific Choices:

- Offshore: Stainless steel connectors with 48-hour salt spray certification.

- Chemicals: Avoid nylon components exposed to acids/alkalies.

Conclusion

A compliant personal fall protection system is a non-negotiable investment for worker safety. Prioritize:

- CE-marked harnesses (EN 361) with valid inspection records.

- Dynamically tested arresters (EN 355) matched to anchor types.

- Engineered anchors (EN 795) verified by structural engineers.

Regular training and system audits are equally vital to maintain compliance with OSHA, EU directives, and ISO 45001.