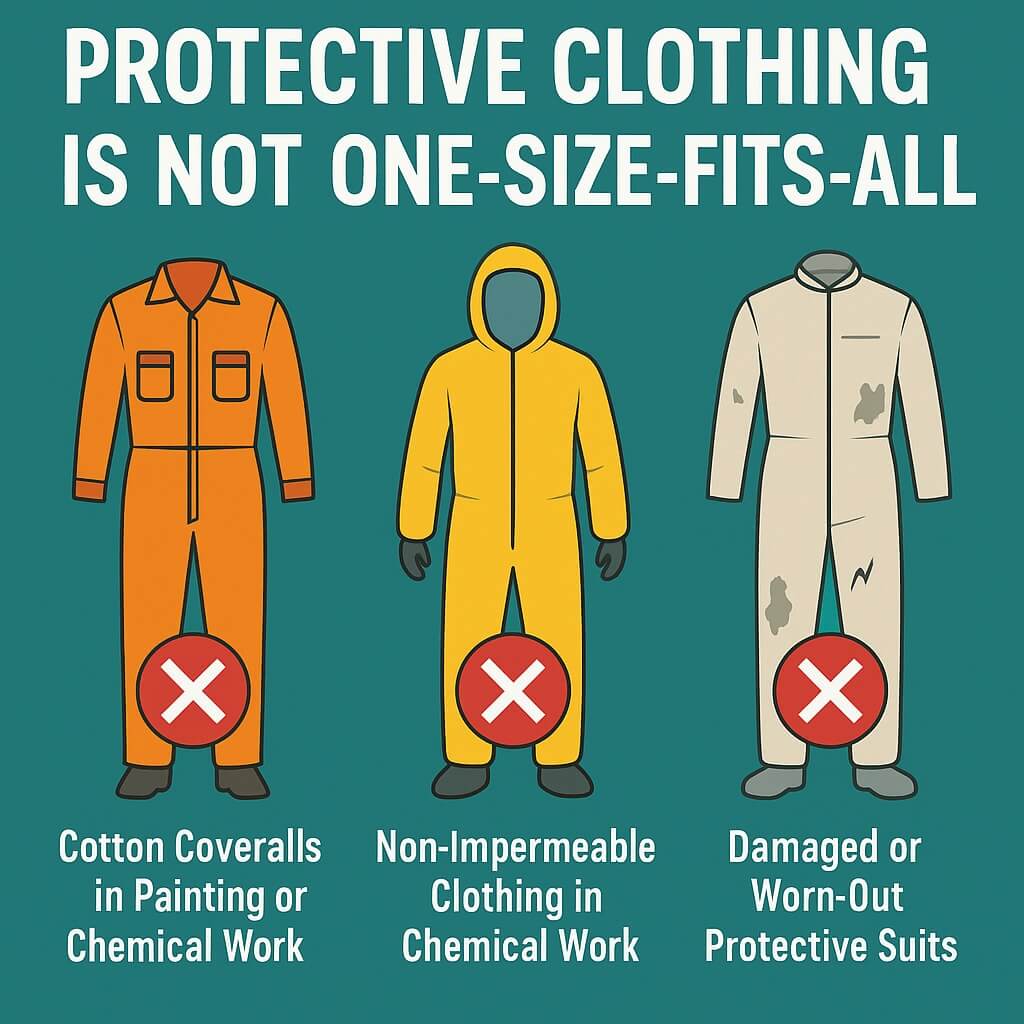

In high-risk industries like chemical handling, painting, welding, and construction, protective clothing is a critical line of defense. But many workers and employers still fall into a dangerous trap — assuming that “any protective suit is better than none.”

Truth is, using the wrong type of protective clothing can actually increase the risk of injury. Here are three real-world PPE mistakes that might look safe, but could be putting your team in danger:

❌ Mistake 1: Wearing Cotton Coveralls in Painting or Chemical Work

Cotton may seem breathable and tough, but in environments where solvents, paint, or thinners are involved, it’s a poor choice. Cotton fabrics tend to:

-

Absorb and retain chemical residues

-

Offer no liquid or vapor protection

-

Catch fire easily when exposed to flammable liquids

⚠️ Risk: In many reported burn cases, cotton clothing caused the fire to spread more rapidly, worsening injuries.

✅ Better Alternative: Use EN 13034-certified chemical splash-resistant suits designed for paint and solvent protection. They prevent penetration and repel dangerous droplets.

❌ Mistake 2: Wearing Non-Impermeable Clothing in Chemical Handling

Even when there are no visible splashes, chemical vapors and aerosols can still harm the skin through permeation. Standard fabrics or poorly sealed garments often:

-

Allow acidic or alkaline vapors to seep through

-

Leave gaps at seams, zippers, and cuffs

-

Fail to create a sealed protective barrier

⚠️ Risk: Many chemical burns and rashes develop hours after exposure due to invisible vapor absorption.

✅ Better Alternative: Choose suits certified under EN 14605 (liquid-tight) or EN 14126 (biological protection), featuring sealed seams, chemical-proof coatings, and ergonomic designs.

❌ Mistake 3: Using Worn-Out or Damaged Protective Clothing

To cut costs, some workplaces keep using protective gear long after it’s damaged, worn, or expired:

-

Fabric loses its flame-resistant or anti-static properties

-

Small tears or weak spots allow dangerous substances to enter

-

Old suits degrade and no longer meet safety standards

⚠️ Risk: Tiny tears = big danger. Even a minor breach can compromise full-body protection.

✅ Better Practice:

Implement regular inspection and replacement policies. One-time-use suits should be discarded immediately after use, and reusable PPE should follow documented replacement cycles.

🧩 How to Choose the Right Suit by Job Type

| Job Role | Recommended PPE Type | Applicable Standards |

|---|---|---|

| Painting / Spraying | Anti-paint splash suits, anti-static | EN 13034, EN 1149 |

| Chemical Handling | Impermeable chemical suits | EN 14605, EN 14126 |

| Welding | Flame-retardant protective clothing | EN ISO 11611 |

| Food Industry | Cleanroom garments, isolation gowns | EN 14126 |

| Dusty Environments | Anti-dust disposable coveralls | EN 13982-1 |

🧰 Featured Products You Might Like

🔍 Final Thoughts

Protective clothing isn’t just about looking compliant — it’s about staying alive and injury-free.

Wearing the wrong PPE is a silent hazard that could cost more than just money. Make sure your team is geared up properly, not just generally.