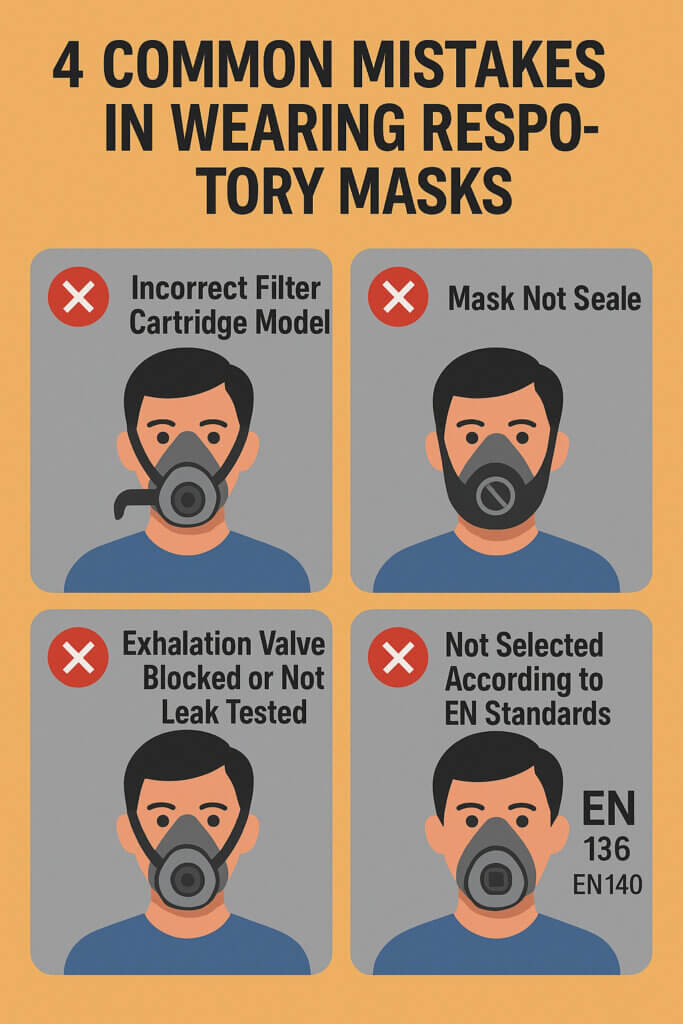

Respirators play a vital role in protecting workers from hazardous airborne substances in high-risk environments. However, even the best respirator can fail if worn incorrectly. In this article, we reveal the four most common mistakes in respirator use that may put your health and safety at risk.

1. Using the Wrong Filter Cartridge: Dust Filters Are Not for Toxic Gases

One of the most dangerous mistakes is using an incompatible filter cartridge. Different cartridges are designed for different hazards:

-

P-type cartridges for particulate matter (dust, mist)

-

A-type cartridges for organic vapors (paints, solvents)

-

B-type cartridges for inorganic gases (chlorine, hydrogen sulfide)

-

E-type cartridges for acidic gases (sulfur dioxide)

Example mistake: Using a dust (P3) filter cartridge in an environment with toxic organic vapors offers no protection against harmful gases.

✅ What to do: Always identify the contaminants in your work environment and select the appropriate filter cartridge with the correct certification and labeling.

2. Poor Seal: Facial Hair Causes Leaks

A respirator’s effectiveness depends on a tight seal between the mask and your face. Common seal issues include:

-

Facial hair (beards, stubble) interfering with the mask’s seal

-

Sweat or oils reducing adhesion

-

Loose straps or incorrect adjustment

A poor seal lets contaminated air bypass the filter, negating the respirator’s protection.

✅ What to do: Shave facial hair where the mask contacts the skin, clean your face before wearing, and ensure proper strap adjustment. Perform a seal check every time you wear the respirator.

3. Blocked or Faulty Exhalation Valve and No Leak Testing

The exhalation valve allows your breath to exit the mask easily while preventing contaminated air from entering. If blocked or damaged, it can cause discomfort and reduce breathing efficiency.

Many users also skip performing a fit check or leak test before use, missing potential leaks.

✅ What to do: Inspect the exhalation valve regularly for blockages or damage. Always perform a positive and negative pressure seal check before entering a hazardous area.

4. Using Respirators That Do Not Comply With EN Standards (EN136 / EN140)

European Norm (EN) standards ensure respirators meet safety and performance criteria. Common standards include:

-

EN136 for full face masks

-

EN140 for half masks

Using non-compliant or unsuitable respirators can lead to inadequate protection or exposure risks.

✅ What to do: Understand your workplace hazards and choose respirators certified to the correct EN standard. Always request and verify product certification documents.

Conclusion: Proper Respirator Use Is Your First Line of Defense

Incorrect respirator use not only renders the protection ineffective but also increases health risks. To protect yourself effectively:

🔹 Identify workplace hazards clearly

🔹 Select the correct filter cartridge and mask type

🔹 Ensure a tight, leak-free seal

🔹 Use EN-certified equipment appropriate to your environment

Only then will your respirator truly protect your lungs and health.